Find a professional Villaboard contractor in Inner South Melbourne

Fill in a short form and get free quotes for local Villaboard contractors in Inner South Melbourne

Excellent rating - 4.3/5 (10900+ reviews)

Get help from a local villaboard installer

- Bathroom walls

- Waterproofing

- Painted villaboards

- … or anything else

Recent Villaboard Installation tasks in Inner South Melbourne

Plaster and villaboard in bathroom

$5,000

Malvern VIC, Australia

22nd Oct 2024

Villaboard on 2 walls plasterboard on stud frame bathroom with w/ in robe Solid brick wall villaboard to clad

Install plaster board and villa board in two small bathrooms

$900

Brighton East VIC 3187, Australia

12th Jun 2023

Two small bathrooms 2m x 2m x 2.6m ceiling and walls to be plaster boarded up. All materials supplied and ready to go. All noggins in place just need it all fixed. - Due date: Flexible

Reliable and did a great job. Would definitely recommend.

What is Airtasker?

Post your task

Tell us what you need, it's FREE to post.

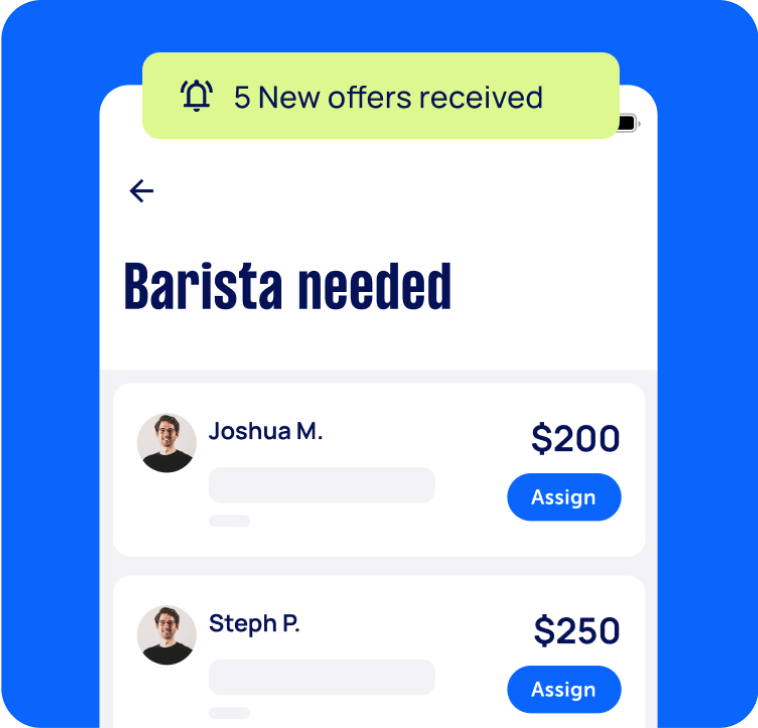

Review offers

Get offers from trusted Taskers and view profiles.

Get it done

Choose the right person for your task and get it done.

- Get it done now. Pay later.

- Repay in 4 fortnightly instalments

- No interest

- Available on payments up to $1,500

Handyman Services

Attic Ladder Installation

BBQ Repair

Bed Repairs

Bistro Blind Installation

Blind Repairs

Blueboard Installation

Cat Door Installation

Ceiling Fan Repair

Cement Sheeting Installation

Chicken Coops

Clothesline Installation

Cornice Repair

Curtain Rod Installation

Door Installation

Door Knob Installation

Fireplace Installation

Fitness Equipment Installation

Flyscreen Installation

Garden Shed Installation & Repair

General Labour

Gyprock Installation

Hills Hoist Removal

IKEA Benchtop Installation

Internal Door Installation

Kaboodle Kitchen Installation

Kitchen Cupboard Repair

Kitchen Drawer Repair

Kitchen Sink Installation

Lattice Installation

Lounge Repair

Mirror Repair

Outdoor Blinds Installation

Pet Door Installation

Privacy Screens

Recliner Repair

Roman Blinds Installation

Screen Door Hinge Repairs

Shower Screen Installation

Sign Hanging

Sink Installation

Sliding Door Repair

Soundproofing

Trampoline Repair Service

Venetian Blind Repair

Water Tank Installation & Repair

Weatherboard Repair

Window Frame Repair

Window Repair

Roller Shutter Blinds Repair & Installation

Ring Doorbell Installation

Clock Repair

Tool Repair

Render Repair

Treadmill Repair

Letterbox Replacement

Toilet Seat Fitting

Awning Repair

Mirror Cutting

Ceiling Fan Installation

Chandelier Installation

Wooden Blind Fitter

General Maintenance

What does a Villaboard installation include?

Your installer can help with every step from advice on the best materials through to the actual Villaboard installation. Here’s what you can expect:

Villaboard wall installation

Your installation professional will start by helping you choose the right type of Villaboard sheeting. 6mm is standard for residential applications, while commercial applications usually use 9mm or 12mm in heavy-duty situations. If your existing wall sheeting needs removal, they’ll assist with this, but otherwise, they’ll get straight into measuring the space to determine the best placement for your Villaboard installation. Your installer will add internal angles into any corners before they start. They’ll work from ceiling to floor, so they’ll need to start by installing a nail ledge on the joist to rest the top sheets on. Lifting and installing Villaboard is a two-person job because they’re very heavy materials. They’ll rest the panel on the nail ledge, slide it into place, and nail it into the studs. Once the top row is installed, your installer will add the bottom row, staggering the sheets to avoid floor to ceiling join lines. If a panel needs holes for electricals or plumbing, your technician will mark and cut these holes before installing. If they need to cut smaller pieces, they’ll use a special cutter to cut the board down to size. Your installer will continue working until all gaps are covered. Finally, they’ll patch up any joints and nail holes by applying coats of compound and paper tape, smoothing the surface as they go.

Villaboard ceiling installation

Installing Villaboard ceilings is a similar process. Your installer will use both nails and adhesive to secure your staggered sheeting to the framing. Once both your ceilings and walls are installed, they’ll finish off the joints and corners and cover up nail holes with compound. Then they’ll install regular plaster cornices using adhesive and setting compound.

Villaboard repairs

Villaboard is a tough material but it can sometimes need repairing, especially if you’ve removed tiles from the surface during a renovation. If it’s a very small hole, crack, or scratch, your technician may be able to use compound to patch the surface. But if it’s a larger hole, your technician will cut around it to make a clean shape, then they’ll cut a matching shape from wood to fit into the hole. They’ll secure this with stud adhesive and screws before covering the surface of the wood with gyprock compound. Once dry, they’ll sand this back to smooth, vacuum away the dust and apply a thin topcoat of compound. Finally, they’ll sand once again and it’ll be ready to paint.